An automatic capping machine is essential in making certain product quality, stability and quality. Nonetheless, few recognize the vital function that torque testing plays as well as factors which affect the overall accuracy. Today’s manufacturing operations are really concerned with loosened or removed caps which will plainly impact product freshness, item security, shelf-life and possibly leak.

Challenges of capping in the past

In the past, cap force screening was as easy as getting a canister from the production line and manually examining how tight the cap felt. As a result of the intuitive sensation of cap rigidity, with time, the market moved towards utilizing much more unbiased dimension gadgets.

Due to the large variety of serration kinds and also cap diameters, a quality department is challenged with the significant expense of adjustment components as well as the management of the numerous irregular parts. Other disadvantages include the problem of lining up the part with the clamped bottle/cap as well as the inability to collaborate with smooth fasteners, pump dispenser lids and other distinct closure styles.

Why Utilize Capping Machines?

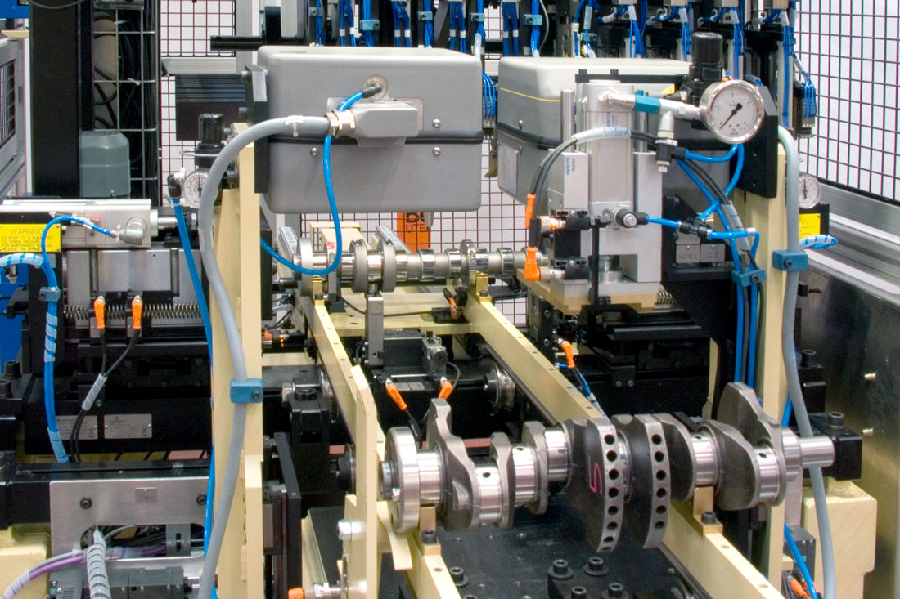

Mechanical Capping Machines not only speed up the process of completing packaging of your item, but they also ensure that each cap is hygienic and that the product does not get infected by handling. Furthermore, they permit you to conserve oneself from the recurring activities of positioning and also fastening caps to each bottle yourself. There are a variety of different capping machines that can help you bundle extra product in much less time– and also not just the machines that put the lids on, either.

Integration right into an existing system.

Exactly how will the capper fit in to your prevailing system? Do you need a standalone layout for easy integration into the line? Gating options including choice of feedscrew? Does the capper require to react with prevailing equipment? Exactly how disruptive will the addition of a new capper be to your system? Can the capper be set up on a current conveyor? Is it equipped with item handling that works with your line?

Easy Combination

Most of mechanical cappers available right now can integrate easily with your prevailing packaging line. The tabletop versions of our item make it basic for any individual to begin packing a product promptly, without having any other tools, as well. This renders it a flexible and also must-have addition to your procedure.

Versatility

The majority of auto cappers have the ability to take care of a range of cap dimensions as well as types, provided that the tightening principle remains the very same. For instance, a pin capper is used for fastening on a spiral cap. With mechanical spindle cappers, the equipment can additionally take care of turn tops, sports caps, level caps, and also activate sprayers. Numerous cap sizes will typically call for a simple, tool-free modification or change over when relocating from one scale to one other.

Leave a Reply